From 2007, we are specialized in Automation, Plastic Welding Systems, Textile and Agriculture Systems. Being curious about new application fields, we have decided to explore other industries, such as:

- Beauty, where we produce manual tools for the extensions fixing

- Non-destructive testing, for which we realized a tailor-made ultrasonic system for the measurement of geological samples features

- Security systems, where we designed electronic boards for access control through smartphone, Bluetooth board, keyfod and cloud, in collaboration with 123Lab and Disec srl.

In this section, we collected some case studies for each industry.

Automation, Plastics welding, Filtration, Medical

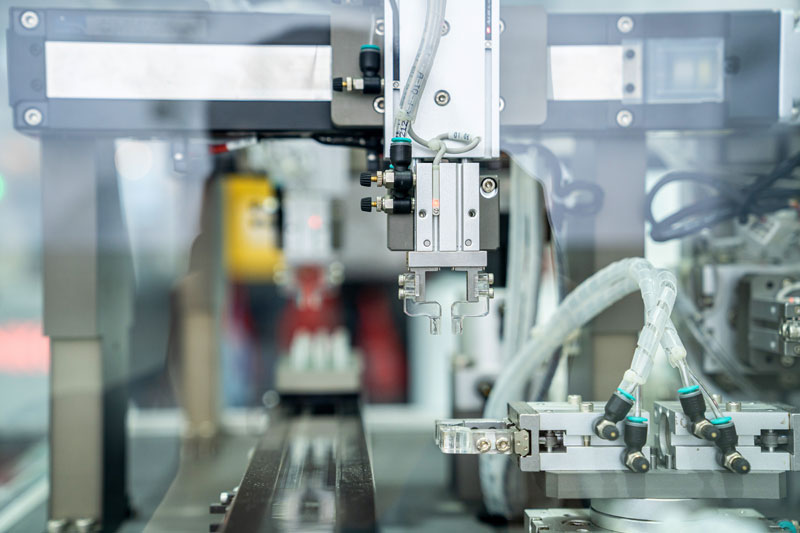

- GOALS: Developing of PLC program; user interface.

- PROJECT: Program realization for rotating table aimed at welding plastic, with conveyor belt for scrap parts and pick&place system to move the good ones. The machinery allows to assemble plastic parts, to assess whether the welding quality is good and to remove the poor-quality parts in the dedicated area. The system has been realized by means of our ultrasonic generators.

- ACTIVITIES: PLC Mitsubishi program development; development of Kinco user interface; collaboration with the customer to establish the features of the machine and input/ouput to use.

Textile

- GOALS: PLC program development and user interface development for a TNT welder machine.

- PROJECT: Program realization with 2 cam electric motors for a ultrasonic sewing machine composed of: welding wheel, foot for speed tuning. The program helps welding TNT fabrics or plastic-based (i.e swimwear for professional and amateur competitions). System realized with our ultrasonic generators.

- ACTIVITIES: PLC Mitsubishi program development to manage 2 cam electric motors; development of Kinco user interface; collaboration with the customer to define the features and input/output to use.

Geological

- GOALS: System to measure the geophysical characteristics of geological samples of the ground.

- PROJECT: The system allows to measure simultaneously up to 6 samples, thank to ultrasonic cells. It is equipped with graphic interface developed in QT, which is installable on Windows. It allows also to manage the timing and the intensity of measurement signals; it is equipped with output for managing pneumatic pumps, it visualizes measures charts and saves all reports.

- ACTIVITIES: Collaboration with the customer to define the specifics for input and output; design and realization of the measurement ultrasonic cells; definition of the parameters to be visualized through the PC interface and developing of PC application.

Agri-tech

- GOALS: To develop a PC interface for remote control of Silos plants and drying rice systems; develop a PLC program for machine-PC communication; system revamping to meet Industry 4.0 requirements.

- PROJECT: Realization of the interface/user panel with SoftGOT Mitsubishi in order to work with our customer’s machinery, aimed at managing the drying and storing processes of rice. The system revamping had to be carried out in order to meet the Industry 4.0 legal requirements, thus allowing the user to check the plant status remotely and upload different programs for rice processing. Beyond the software development, the PLC Mitsubishi program was developed to allow the exchange of information between the system and the existing PLC.

- ACTIVITIES: Collaboration with suppliers to define the graphic aspect, the information to be visualized and the definition of the exchange variables between our system and the customer’s. Development of SoftGOT interface (virtual HMI working for Windows), development of PLC Mitsubishi; report and download of data sheet for output management.

Security systems

- GOALS: Hardware development for lock doors mechanization.

- PROJECT: Design of an electronic board to locate inside a door knob to be installed on the inner panel. It adds new automatic functionalities to the lock system: access controls, block system, intrusion attempts alerts.

- ACTIVITIES: Design of the electronic boards; search of parts; design matching; collaboration with the customer for product engineering.