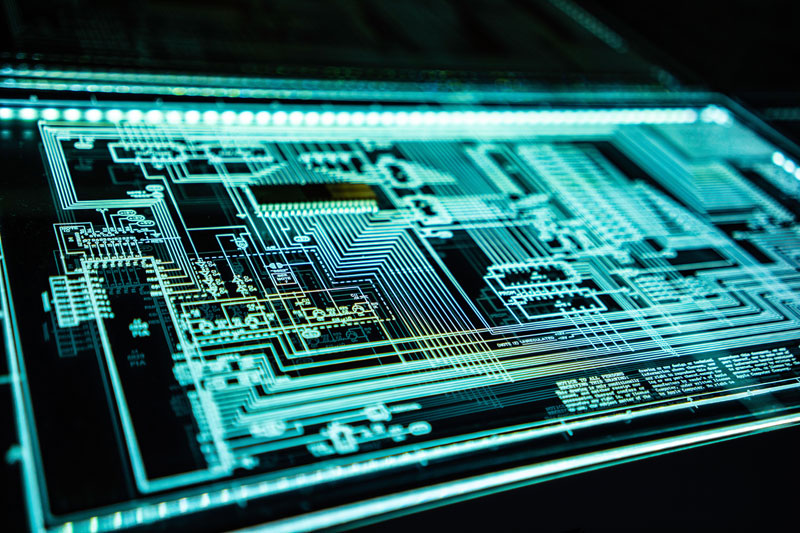

DESIGNING

We take care of the feasibility study according to customer’s needs and project, defined also in collaboration with our suppliers. After realizing the schematics, we search for parts, according to costs and availability. We have always worked with established international brands for the electronic parts. Lastly, we design the final draw of the board.

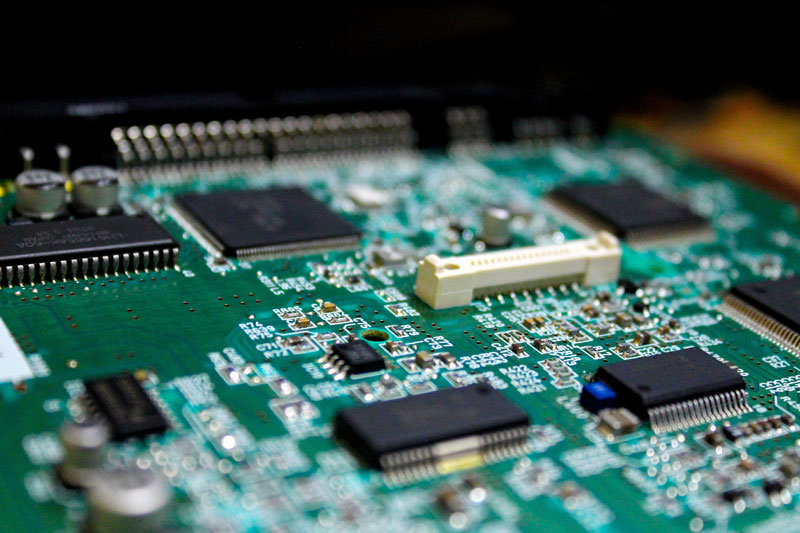

PRODUCTION

We make prototypes designed with the aim of checking the proper functioning and spot errors and failure in the designing process. We are able to industrialize our projects to match them with specific production needs. We optimize our boards to reduce the need of manual interventions (wiring and fittings) in the final assembling of the product.

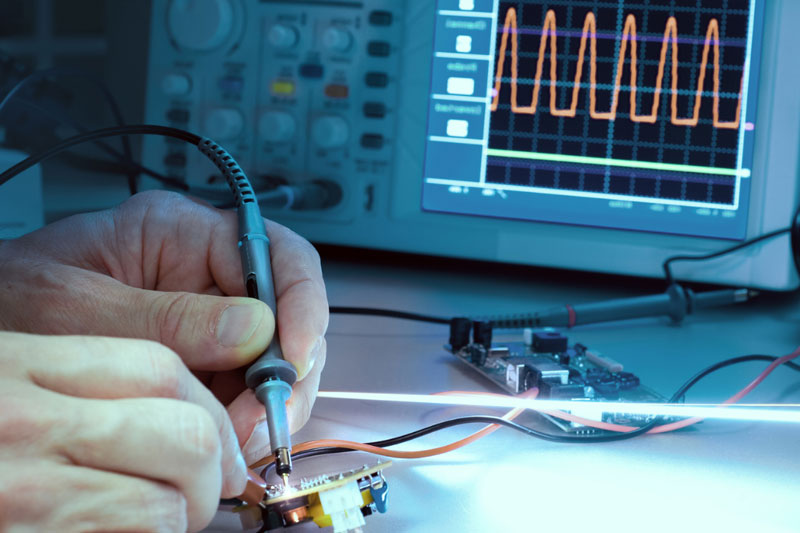

ASSEMBLYING, TESTS AND CERTIFICATIONS

(CE, EMC, UL)

We carry out tests and calibration of tools directly in our laboratory, besides checking the proper functioning of final products. We can provide the support for certifications required in several markets (CE for European Union; UL for USA and Canada) and for specific electromagnetic compatibility tests.

AFTER-SALES SERVICES

We stay in touch with our clients in order to ensure the best experience of the products. If required, we are always available to update or modify the software and hardware, in order to match all products to the latest market evolutions. Moreover, we also take action in case of breakdowns.